We have a whole assortment of Flow Measurement Meters.

Our Coriolis flowmeter consists of two parallel tubes that are made to oscillate using a magnet. These oscillations are recorded by sensors fitted at the inlet and outlet of each tube. In a no-flow state, the oscillations are synchronized, i.e. in phase with each other, since there is no mass exerting any force on the tubes. On the other hand, any fluid, or gas flowing through the tubes generates Coriolis forces, causing the tubes to twist in proportion to the mass flow rate of the medium.

The magnitude of this twisting is measured by the sensors as a phase shift between the inlet and outlet of the tubes; this phase shift is used to measure the mass flow rate of the medium.

See data sheets for complete specs

See data sheets for complete specs

See data sheets for complete specs

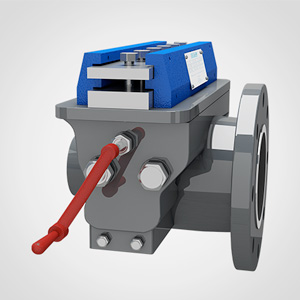

The single chamber fittings are manufactured in accordance with ANSI, AGA/API, and ASTM standards for pressure tap integrity, positive plate seal, seal protrusion, and eccentricity. These single chamber orifice fittings can be installed in vertical or horizontal lines and are available in a wide range of pipe sizes from 2″ to 48″. These fittings allow ease of orifice plate replacement or inspection in a depressurized flow line without physically removing the meter from the line. The Tek-DP 1610A Single Chamber Orifice Fittings are best used in the applications where replacing the orifice plate under pressure conditions is risky and a nominal shutdown time is acceptable. The plate removal procedure does not require removal of the flange bolts or spreading of flanges. This prevents potential leakage of process fluid and safeguards the operators.

See data sheets for complete specs

See data sheets for complete specs

See data sheets for complete specs