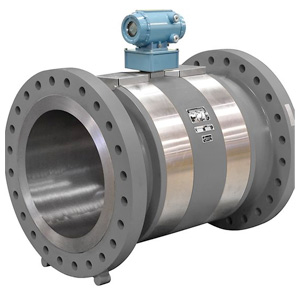

Daniel 3814 Four-Path Liquid Ultrasonic Flow Meter

Daniel 3814 Four-Path Liquid Ultrasonic Flow Meter

Daniel 3818 Eight-Path Liquid Ultrasonic Flow Meter for LNG

Portable Ultrasonic Clamp On Flow Meter PF220A/PF220B

Portable Ultrasonic Clamp On Flow Meter PF330AB

Portable Ultrasonic Clamp On Ultrasonic Flow Meter Waterproof PF440IP

Inexpensive Clamp On Flow Meter Ultraflo U1000

Clamp On Ultrasonic Flow Meter Ultraflo U3000 – U4000

U1000HM Clamp On BTU Meter