Mechanical Level Measurement

Kenco Engineering Company is committed to delivering the highest quality products and service possible, which exceed our customer expectations. Customer satisfaction, excellent engineering and operational performance are considered paramount for us to be a successful company. We strive to improve and fulfill these commitments by establishing quality objectives, which are continually measured, monitored, and reviewed by every level of our management team.

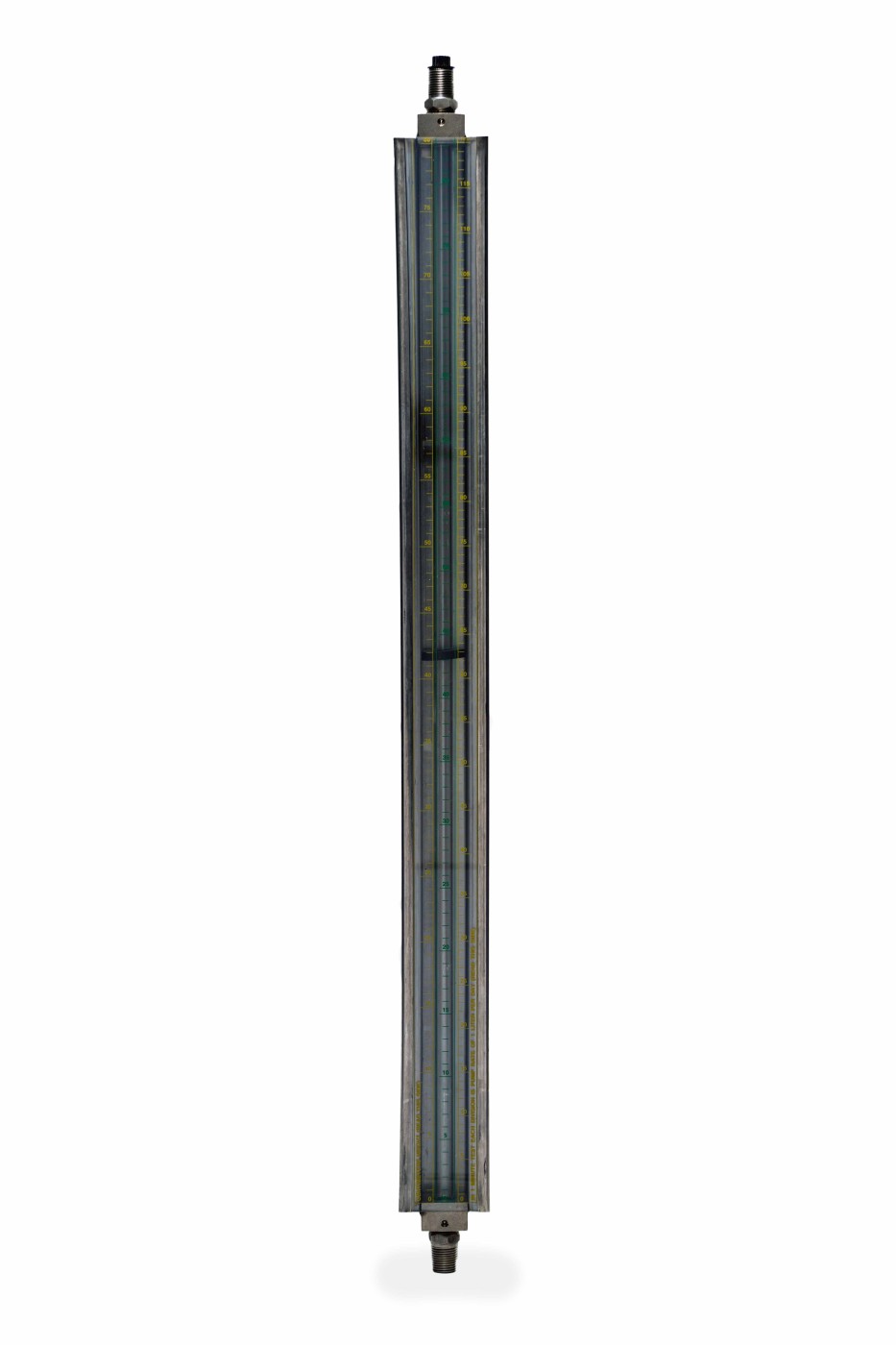

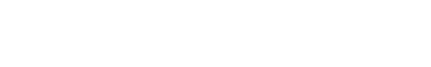

KMR & KHR Reflex Level Gauges & Valves

KMT & KHT Transparent Level Gauges & Valves

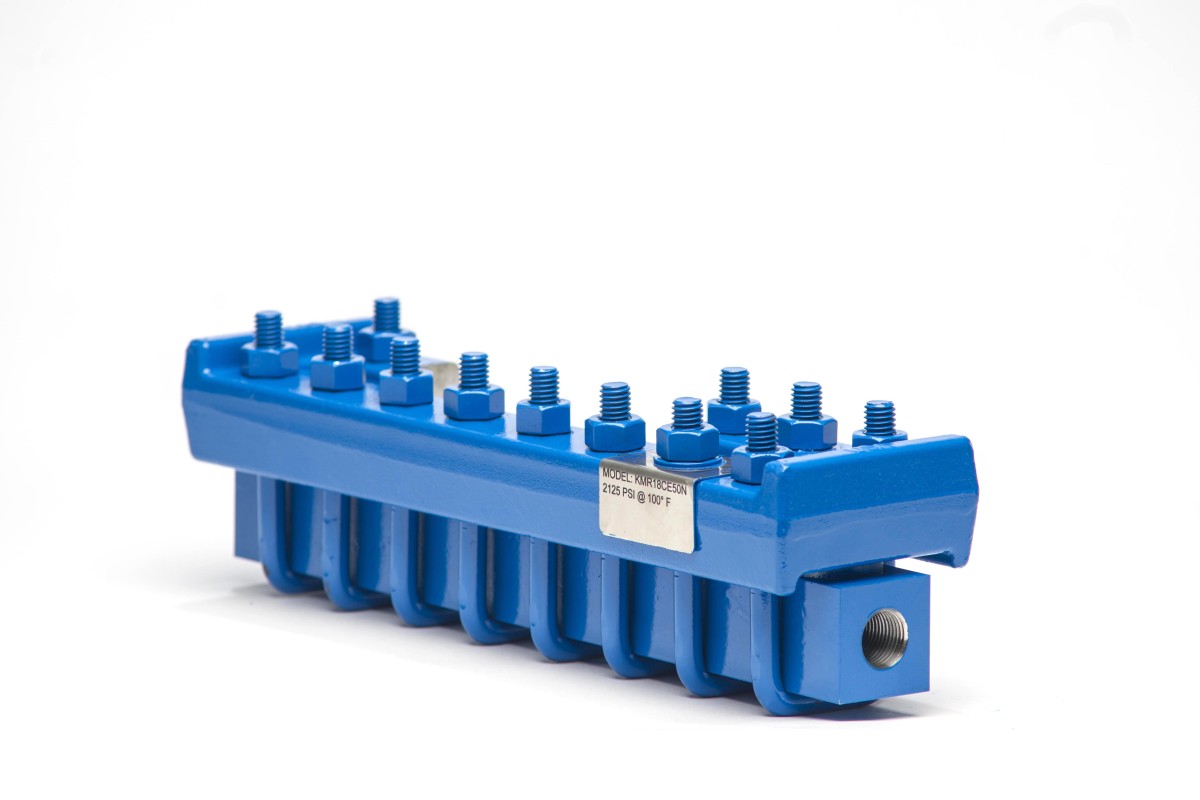

Magna-Site™ Magnetic Level Gauge

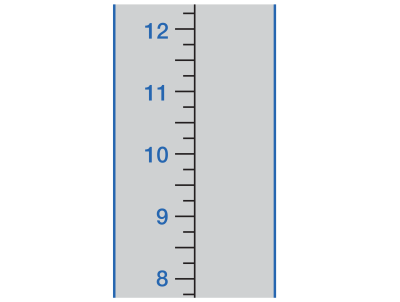

K9900 Series Level Gauge

5700 Bulk Tank

Gauge

SafeguardLevel

Gauge

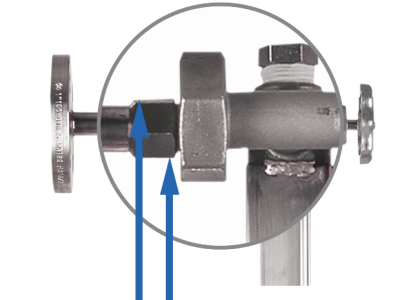

KTV Tubular Valves for Level Gauges

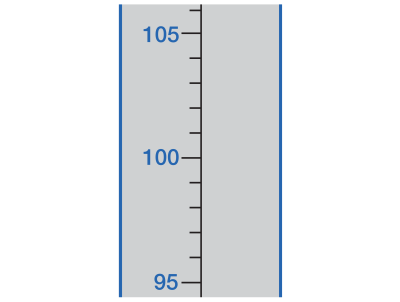

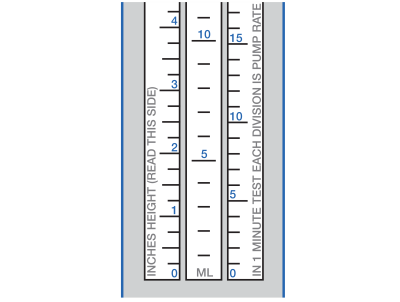

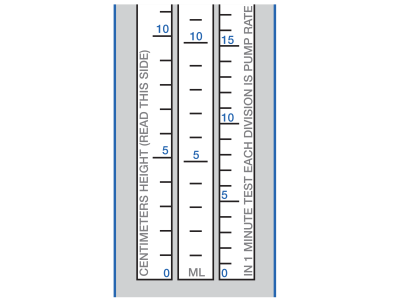

5700 Injection Rate Gauge